Ore-Eye

Welcome to Ore-Eye - the revolutionary online analyzer that can transform your mechanical sampler into a high-tech, real-time process control solution. Our innovative system is equipped with a Microwave, Near-Infrared Sensor (NIR) and Advanced Machine Learning technology, which provides accurate chemical analysis of your raw material feed on a conveyor belt.

What is Ore-Eye?

Ore-Eye is an online analyzer that can be used to monitor and analyze the chemical composition of your raw materials. Unlike other online analysis systems, Ore-Eye is a fully self-calibrated system that synchronizes with your mechanical sampling system and uses existing lab analysis data to self-calibrate the sensor array automatically. This means that there is no need to collect spatial reference samples or do routine calibration.

What samplers can be used?

Ore-Eye is compatible with any mechanical sampler that is used in your process. This includes Cross Belt Sampler, Rotary Hammer Sampler, Vertical Chute Sampler or Rotary sampler. Ore-Eye system monitors when your mechanical sampler is activated, and after the chemical analysis of the taken sample is available from the lab, Ore-Eye uses this information to self-calibrate the online measurements.

Why should you consider Ore-Eye?

Ore-Eye offers a hassle-free online analyzer for your real-time process control needs. With Ore-Eye, you can convert your existing samplers to an online analysis solution, which provides real-time data for process control. The data can be integrated into your process control to make sure that your raw material and final product meet set parameters at all times. This can ensure higher recovery of minerals, reduced consumption of raw materials, energy, and lower CO2 emissions. Additionally, with advanced real-time process control, you can limit the emission of harmful materials such as sulfur and heavy metals.

Use Case

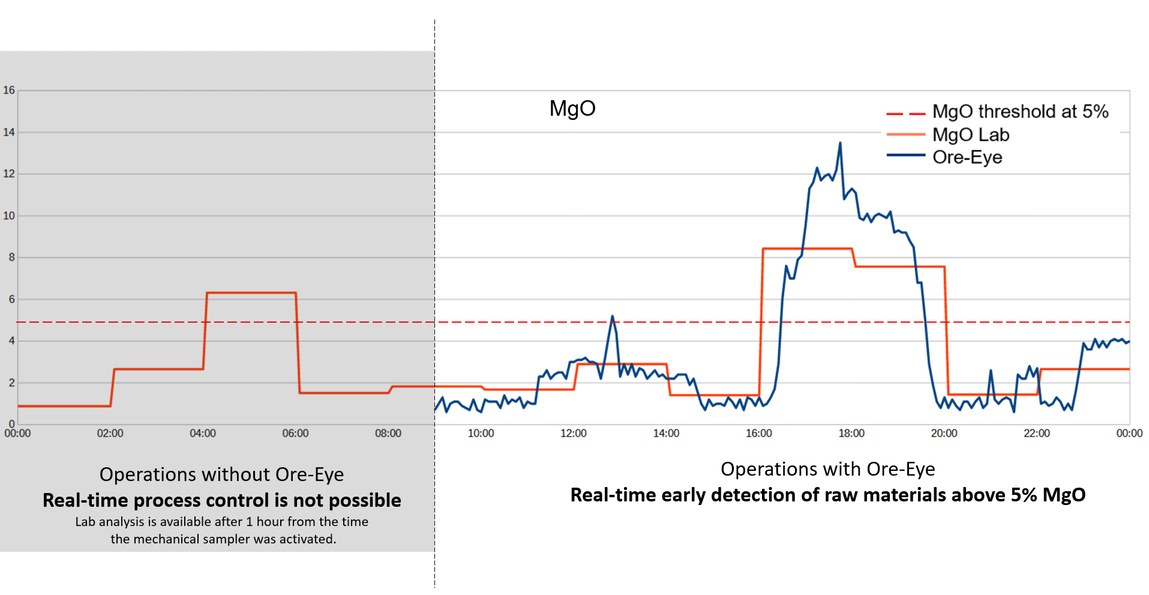

Before Ore-Eye, a calcium carbonate manufacturer relied on a mechanical belt sampler to collect samples for lab analysis once every 2 hours. The lab results were only available after 1 hour. Unfortunately, any ore higher than 5% of MgO resulted in a final product that failed to meet customer requirements, causing a loss of revenue.

Ore-Eye is installed on a conveyor belt next to a mechanical sampler. Ore-Eye records when the mechanical sampler is activated and self-calibrates using available lab data. After just one week of self-calibration, a comprehensive MgO calibration curve is built automatically, and Ore-Eye is ready for full operational mode.

The operator can monitor MgO levels in the ore on the conveyor belt in real-time. Any ore above 5% of MgO can be removed from the production line immediately, ensuring the final product always meets set requirements.

Upgrade your production line with Ore-Eye and eliminate revenue loss due to inconsistent product quality.